Umbilical termination failure and loss of ROV

- Safety Flash

- Published on 21 December 2018

- Generated on 10 February 2026

- IMCA SF 29/18

- 2 minute read

Jump to:

An ROV system had just completed a test dive to 3000m and was being returned to deck.

What happened?

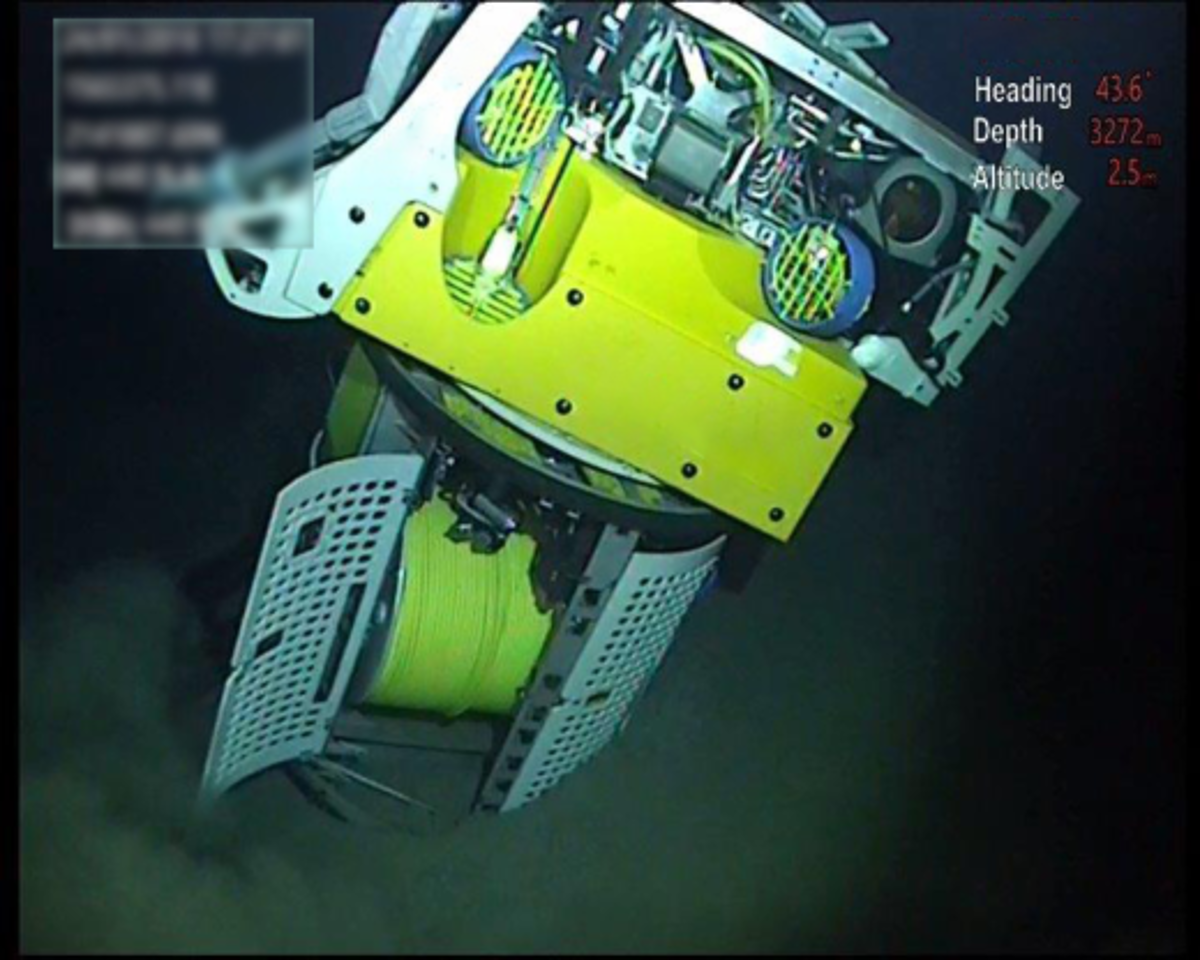

Upon lifting the system out of the water, the umbilical became detached from the TMS bullet. The ROV and TMS fell to the seabed and landed upside down on a firm seabed at 3276m water depth. The vehicle was located by another ROV system from the same vessel. The system (ROV and TMS) was inspected on the seabed. Based on that information and the sea conditions (1.5m significant wave height), a risk assessment and a toolbox talk (TBT) were carried out which determined that recovery was both safe and possible. The spare bullet was terminated onto the ROV umbilical to allow it to be used to recover the system with the emergency recovery rigging on the TMS. The ROV, TMS and umbilical termination were damaged in the incident. No personnel were injured.

What went wrong?

The parted umbilical termination was analysed by a third-party specialist laboratory. Following a detailed engineering examination and internal investigation, it was concluded that the umbilical failed because its termination had been conducted in a very poor fashion with a number of clear defects observed.

- It was noted that the subcontract technician doing the termination did not demonstrate appropriate skill in how to conduct such terminations, and it was clear that procedures were not followed.

- There was an over-reliance in each link of supply chain delivering a quality product, rather than following appropriate checking or verifying of quality.

What actions were taken? What lessons were learned?

- Umbilical re-termination procedures were revised to provide clearer instruction and now include requirement for photographic evidence showing completion of each main step.

- Umbilical termination considered a critical point of assembly therefore quality control processes should be followed to confirm appropriate surveillance is applied to sub-contractor.

Related Safety Flashes

-

IMCA SF 08/15

5 June 2015

-

IMCA SF 06/13

3 May 2013

-

IMCA SF 18/09

22 December 2009

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.