Vessel made contact with quay

- Safety Flash

- Published on 6 December 2016

- Generated on 27 February 2026

- IMCA SF 33/16

- 3 minute read

Jump to:

A member has reported an incident in which a vessel landed heavily on the quay, causing damage.

What happened?

The incident occurred during the hours of darkness, during shifting of the vessel’s position at the berth. The shifting plan was discussed between the Master and the pilot and information was exchanged. The vessel’s position was agreed to be adjusted to meet the terminal’s requirements for cargo offloading. Two tugs arrived and the shifting operation began. The main engine and bow thruster were on standby and used as required.

The operation proceeded as planned and the vessel came gently to a stop, parallel to berth about 2 metres out. At this time, an unloading boom needed to be deployed. It was found that this could not be deployed whilst the vessel was in this position, as there was fixed equipment on the berth in the way. After further adjustment of vessel position, the unloading boom was swung out.

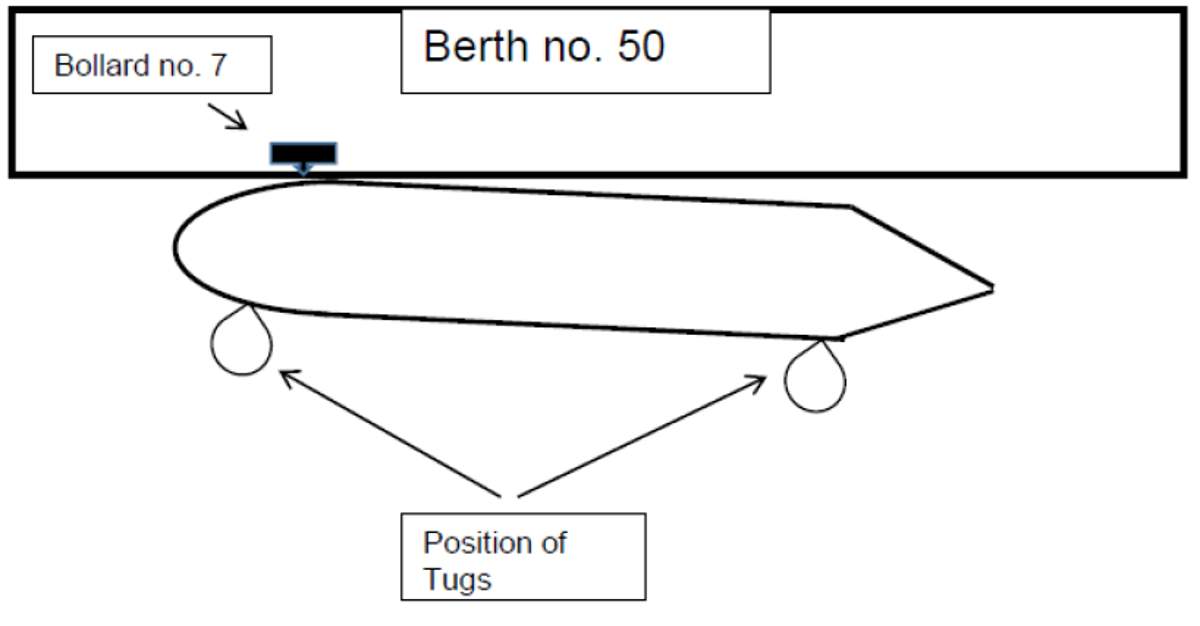

The Master requested that the Pilot take extra care as the vessel was brought alongside. However, as the vessel was being pushed towards the berth both tugs failed to push in harmony. The after tug pushed more and instead of landing parallel to the berth, the vessel’s port quarter landed heavily on the quay near Bollard 7. The vessel’s port side shell plating was damaged near a fuel oil tank, and there was damage to the concrete of the quay itself.

Our members’ investigation noted the following:

- Although the shifting plan was discussed verbally, there was no evidence of a risk assessment being carried out for this operation.

- The Master and the Pilot had not agreed on a working language during their discussion and information exchange.

- The Pilot was using French rather than English to instruct the crew of the tugs.

- The Master and bridge team did not intervene with the Pilot to verify commands given to the tugs in French.

The immediate causes were determined to be:

- The Pilot misjudged the tugs pushing power.

- The pilot was giving instruction in a language which was not understood by the bridge team.

A causal factor was inadequate communication – the Master failed to intervene with the Pilot when instructions to the tugs were given in a language he did not understand.

The root causes were identified to be:

- Risk considered tolerable – this was considered by the Pilot to be a routine recurring task.

- Inadequate Standards – there were no company procedures to cover the situation, particularly with regard to the working language on the bridge during navigational operations where Pilot/tug assistance is required.

Our member took the following preventative actions:

- Remind Masters that they should override the Pilot’s instructions if they are considered to be incorrect or unsafe.

- Establish formal working language for ship’s movement at all times including berthing/un-berthing operations.

- Ensure compliance with guidelines on relationship between Master, Officer of the watch (OOW) and Pilot.

Related Safety Flashes

-

IMCA SF 10/16

18 April 2016

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.