Unexpected truck movement caused rigger to fall off a ladder

- Safety Flash

- Published on 16 December 2020

- Generated on 18 July 2025

- IMCA SF 34/20

- 2 minute read

Jump to:

What happened?

An unexpected movement of a container loaded truck during disconnection of the container’s rigging, caused a rigger to fall off a ladder leaning against the container.

Two containers were being loaded onto a trailer truck using a mobile crane. The supervisor conducted the toolbox talk before starting work. The riggers removed the container’s rigging (chain hooks), using a ladder to access the connection points.

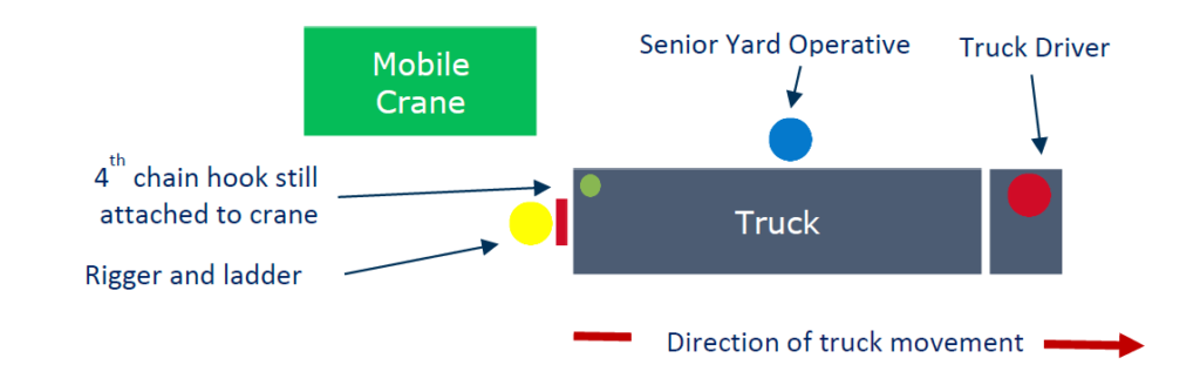

The first container was loaded without incident. The second container was loaded onto the trailer and the riggers began to remove the chain hooks whilst the supervisor and driver secured the twist locks. To access the 4th and last chain hook the rigger positioned the ladder against the rear of truck trailer.

After securing the twist locks the driver went to the cab. He checked the side mirrors and could only see the supervisor, and so proceeded to drive forward, assuming the lifting crew had already de-rigged the container.

The rigger was approximately one metre above the ground and the 4th chain hook was still attached to the container and the crane, when the truck moved forward.

The driver heard people shouting, and stopped the truck after it had moved around half a metre forward. Due to the truck movement, the rigger slipped off the ladder, sustaining bruising to his leg.

What went wrong?

Findings were:

- The supervisor did not provide the driver with an induction or briefing when he arrived at the yard.

- The Permit to Work for Working at Height indicated that a free standing work platform was to be used, but this was not used.

- The driver assumed that he was clear to drive forward.

- The Task Risk Assessment did not assess the risks introduced by or to the driver.

Actions

- Ensure clear and fully understood communication with third party plant operators – the truck driver in this case – before starting work.

- Ensure formal control of work, instructions, risk assessments and communications protocols are in place for third party drivers and other personnel.

- Consider keeping the driver away from the job completely until the lifting operations is complete. This prevents drive off and protects the driver from potential lifting issues impacting the driver’s cab.

Related Safety Flashes

-

IMCA SF 19/20

23 June 2020

-

-

IMCA SF 28/17

7 November 2017

-

-

IMCA SF 28/17

7 November 2017

-

-

IMCA SF 22/17

1 September 2017

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.