Rigging failure during riser recovery – soft slings parted

- Safety Flash

- Published on 11 February 2021

- Generated on 4 March 2026

- IMCA SF 05/21

- 2 minute read

Jump to:

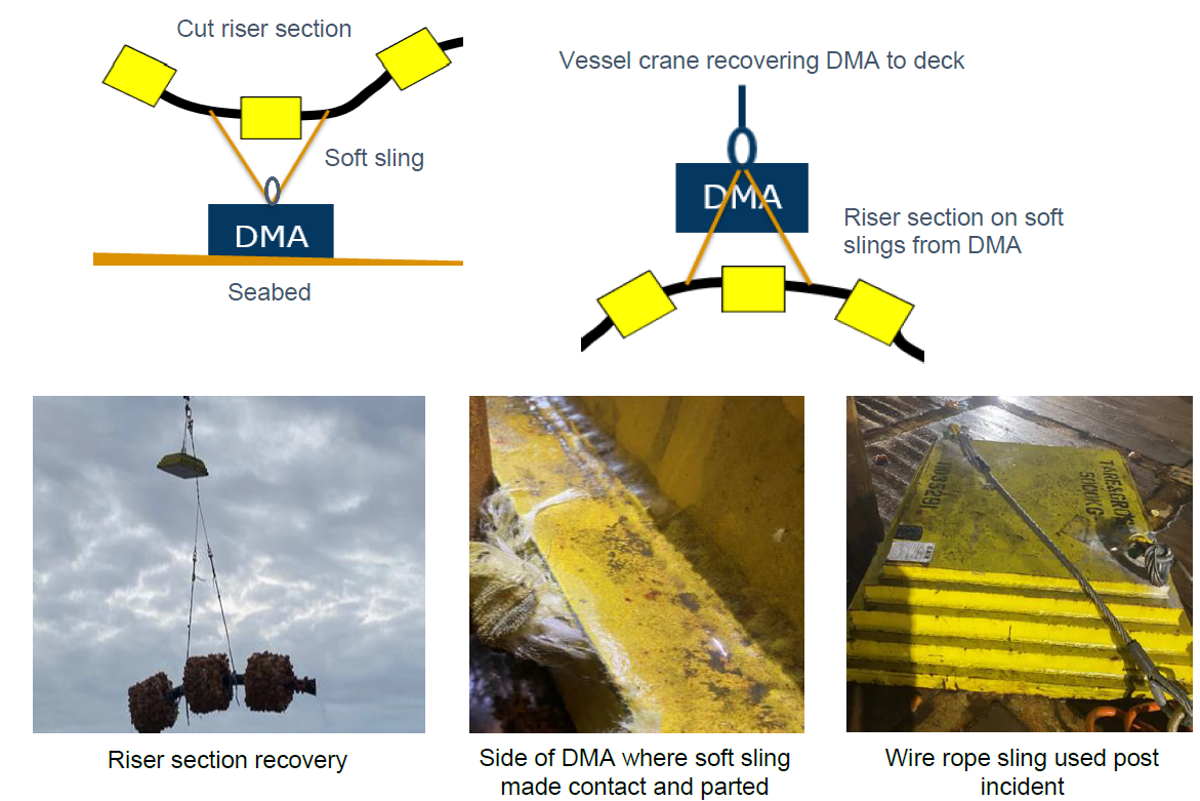

While being recovered at sea, a 10m riser section (3.8 Te) fell approximately 2.5 m to deck when the slings parted after rubbing on the sharp edge of the deadman anchor.

What happened?

During recovery of a 10m riser section with buoyancy modules attached, the riser section dropped 2.5m to deck when the soft slings parted after rubbing on the sharp edge of the Deadman Anchor (DMA). During decommissioning activities, the riser was cut into approximately 10m long sections.

The section had been weighted down with a DMA prior to cutting. On completion, the DMA was recovered along with the riser section suspended below the DMA. When slewing the riser section inboard, the riser section (3.8Te) fell approximately 2.5m to deck when the slings parted after rubbing on the sharp edge of the DMA.

Control measures were being followed with all personnel standing clear of the lifting area, behind the barriers as stipulated by the risk assessment.

What went wrong?

- A pendulum effect occurred whilst the product was draining before recovery onboard, which resulted in the riser section suspended below the DMA moving against the sharp edges on the DMA, and thus cutting the soft slings.

- The sharp edges of the DMA had not been identified as a potential hazard in relation to the use of soft slings.

Actions

- Wire rope slings should be used where slings connect with a DMA.

- The exception would be, unless the use of soft slings has been fully risk assessed with specific consideration given to the possible contact with the edges of the DMA.

- The exception would be, unless the use of soft slings has been fully risk assessed with specific consideration given to the possible contact with the edges of the DMA.

- Consider the use of rounded DMAs where there is a potential for sharp edges to connect with the rigging.

- Consider having pad eyes welded along the bottom profile of the DMA to mitigate against fouling with the rigging.

Related Safety Flashes

-

IMCA SF 10/13

25 June 2013

-

IMCA SF 09/13

18 June 2013

-

IMCA SF 11/06

18 September 2006

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.