USCG: Hazardous Zone Markings and Safety Protocol Awareness

- Safety Flash

- Published on 16 April 2025

- Generated on 26 February 2026

- IMCA SF 07/25

- 2 minute read

Jump to:

The United States Coastguard (USCG) has published Safety Alert 04-25 relating to the importance of Hazardous Zone Markings and Safety Protocol Awareness.

A recent marine incident involving a tri-fueled vessel (liquified natural gas (LNG), diesel, battery) that resulted in a fire and severe injuries to crewmembers highlights the dangers of working in hazardous zones. Despite being aware of nearby crankcase and LNG purge vents in their work area, the crew did not know that the vessel was actively using methane as a fuel source.

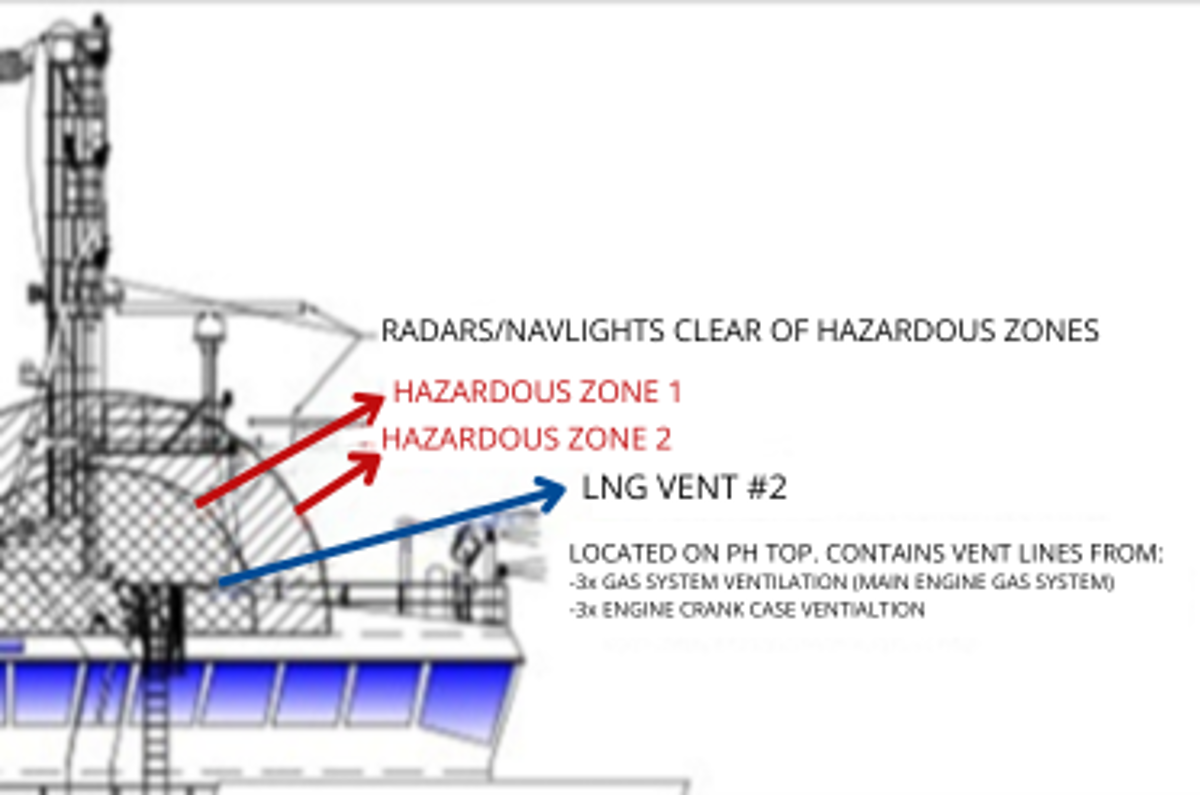

Fig. 1 Hazardous zone on “air castle deck” above pilothouse

Methane vent after the incident

As a result, the work was being conducted in a hazardous zone (see Figure 1). Although marked as a hazardous zone on the vessel’s plans, the zones were not physically or otherwise marked as hazardous on the deck, providing no visual indication to the crew of the potential hazards present. While crew performed assigned work on top of the pilothouse a failed engine purge valve actuator released LNG vapours through the vents located in the crew’s work area. Believing the area was gas-free, a crewmember struck a lighter, igniting the LNG fumes and causing severe injury to both crewmembers.

This incident shows the critical importance of hazard awareness, proper marking of hazardous zones, and strict adherence to safety protocols.

Recommendations

The USCG strongly recommends that vessel owners, operators, and other stakeholders:

- Review hazardous zone requirements and ensure crewmembers are fully aware of the circumstances and dangers that define hazardous areas.

- Ensure all hazardous zones are clearly marked and crewmembers are aware of the locations and associated hazards.

Related Safety Flashes

-

IMCA SF 23/24

27 November 2024

-

-

IMCA SF 18/23

24 July 2023

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.