Equipment damage: Dropped object from tiltable lay system

- Safety Flash

- Published on 20 April 2023

- Generated on 7 February 2026

- IMCA SF 10/23

- 2 minute read

Jump to:

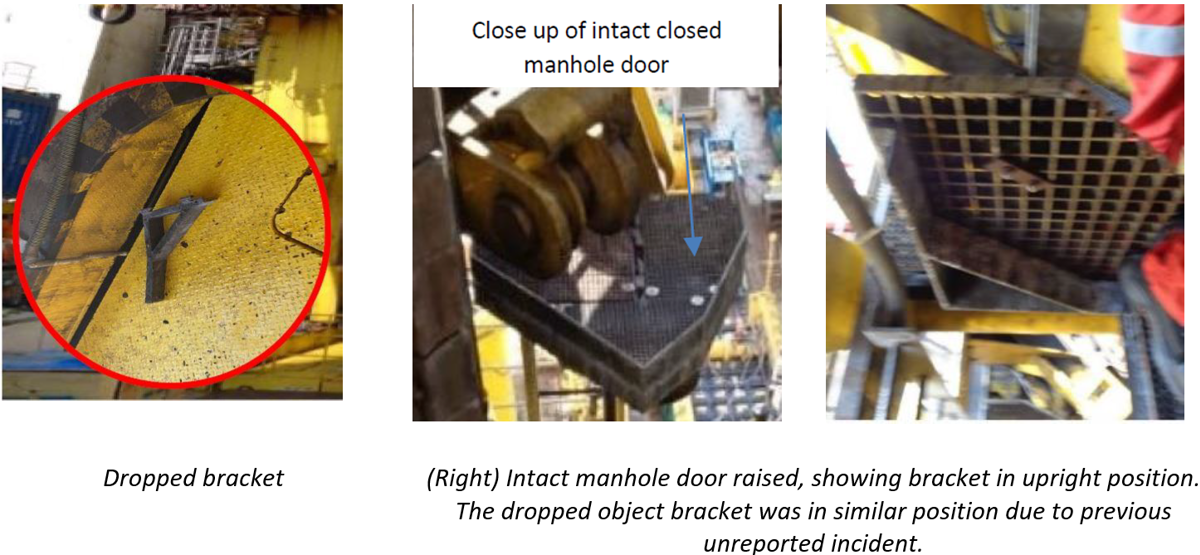

A bracket weighing 10.5 kg fell 16 m to deck.

What happened?

The incident occurred during a function test of a tensioner on a pipelay system. The tensioner doors had to be moved into the firing line, closed, and then retracted to the parked position.

As the tensioner doors were being closed, the port side door made contact with a hinged bracket that was part of an inspection manhole gate which had been left open.

This resulted in the bracket, weighing 10.5 kg, dropping approximately 16 m to the work table below.

What went right?

Robust and stringent controls, restricting personnel from entering the drop zone, reduced the potential for harm.

These included hard barriers at deck level directly underneath the work area, and additional temporary barriers to create a wider exclusion zone to take into consideration the dropped object cone of exposure.

No personnel were in the line of fire at the time of the incident.

What went wrong? What were the underlying causes?

Before this event, the inspection manhole gate had been damaged in a previous unreported incident.

Subsequently some minor repair work had been undertaken which involved the removal of the grating from the gate/bracket. The hinged bracket was seized in the upright position and at the time it was not considered a dropped object hazard due to it being firmly secured to the TLS structure.

- The seized bracket was not fully repaired following the original incident.

- The latent hazard posed by seized bracket was not identified as a potential DROPS or as a clashing hazard.

Lessons learned

- Although the first incident was recorded within the pipelay team handover notes, there was a failure to formally report it within the company incident reporting system – all damage incidents should be reported to ensure the correct level of investigation, and so that corrective and preventative actions are identified and implemented.

- The equipment design and layout failed to identify the clash points created when manhole gates were left in the open position.

Related safety flashes

-

IMCA SF 04/22

10 February 2022

-

-

IMCA SF 23/21

19 August 2021

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.