BSEE: Umbilical termination failure leads to dropped ROV

- Safety Flash

- Published on 18 June 2025

- Generated on 21 February 2026

- IMCA SF 11/25

- 2 minute read

Jump to:

The United States Bureau of Safety and Environmental Enforcement (BSEE) has published Safety Alert 499 relating to a dropped ROV.

What happened?

An ROV was in the process of being recovered after completing an inspection dive. After the ROV was nested in the Launch and Recovery System (LARS) cursor, the unit cleared the surface and travelled along the vessel cursor rails up to the cursor transition point. At the transition point, the operator stopped hauling in the umbilical winch and cursor assist tuggers to switch the umbilical winch to low-tension mode. As the ROV reached the cursor rail transition point, the umbilical parted, causing the ROV to drop to the seafloor.

The ROV was subsequently located and recovered using its transponder. No damage to any seabed assets or harm to personnel occurred.

What was the cause?

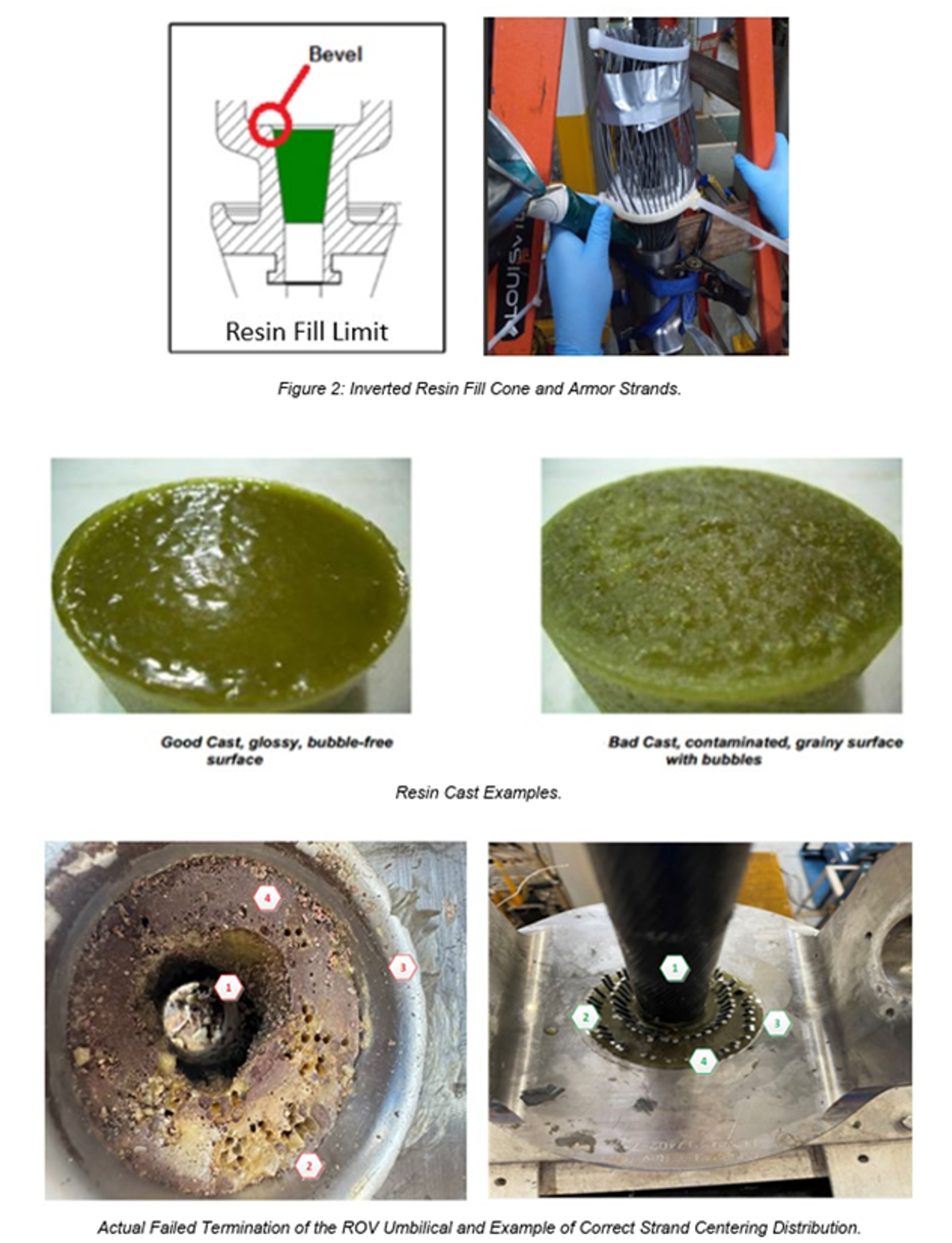

The incident was traced back to a flaw in the initial umbilical attachment. A resin was used to secure the umbilical to the ROV, but the resin case was faulty, and the armoured strands were improperly centred and distributed during the attachment process (Figure 2). Despite passing a previous pull test, the defects led to the failure.

BSEE recommends

- Develop and implement an umbilical termination inspection procedure and training program to ensure proper inspection of resin condition and the assessment of armoured strand separation;

- The program should also include training on re-termination of umbilicals;

- Incorporate umbilical inspections into pre-job checks and maintenance procedures to ensure the integrity of the connection is verified prior to use.

Related Safety Flashes

-

IMCA SF 34/21

9 December 2021

-

IMCA SF 27/19

22 November 2019

-

IMCA SF 29/18

21 December 2018

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.