Davit hook failures

- Safety Flash

- Published on 21 June 2023

- Generated on 11 February 2026

- IMCA SF 15/23

- 2 minute read

Jump to:

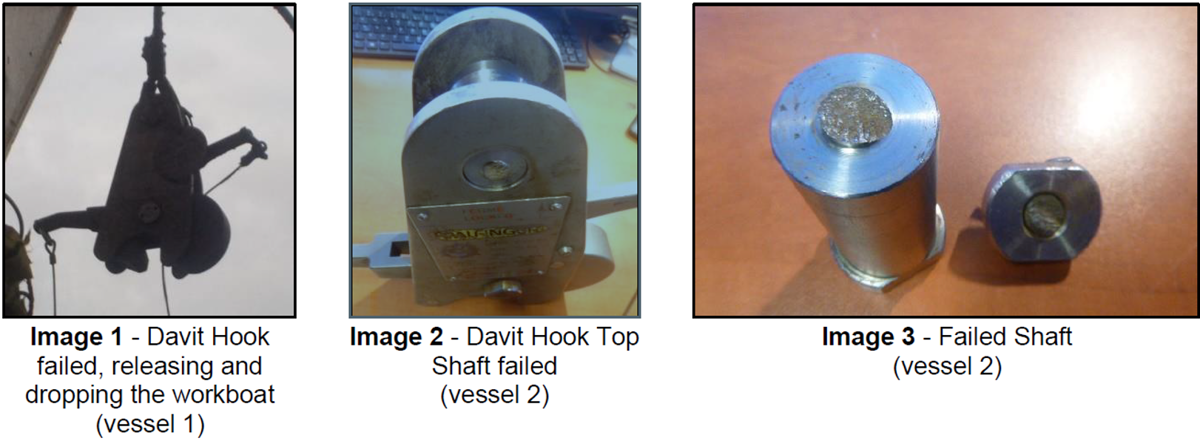

A member reports two separate instances where a workboat davit hook, and life raft davit hook components, have failed.

What happened?

- Incident 1: During a weekly inspection of lifesaving equipment, the workboat davit hook on one vessel failed resulting in the hook releasing and dropping the workboat to the sea. No persons were in the workboat at the time and there were no injuries. However, the workboat itself was badly damaged.

- Incident 2: A subsequent inspection of similar davit hooks on a sister vessel found the top shaft screw had sheared on a life raft davit hook, with the nut having dropped to deck. The shaft remained in place, holding the hook in position.

What went wrong?

- Incident 1: The failure of the workboat hook remains under investigation. Further information will be distributed when the review has been completed.

- Incident 2: The failure of the life raft davit hook was suspected to have been the result of an undetected crack in the threaded section of the hook top shaft screw. This allowed environment conditions to cause deterioration, resulting in the top hook shaft threaded section to shear off the body of the pin. Examination of the shaft showed that the fracture had developed over time.

Actions

Our member took the following actions:

- Halted all non-emergency launch and recovery operations using this type of hook until further notice.

- Inspected all similar davit hooks, paying particular attention to the top and bottom pin shafts and surrounding mounts, inspecting for cracks, deformation or fatigue. For this type of hook, the inspection included disassembly of the top shaft, loosening the securing screw, nut, shaft itself and the distance bush.

- Reviewed onboard maintenance regimes to ensure inspections of davit hooks include checks on the davit hook pins to identify any physical deterioration.

- Confirmed that the most recent annual inspection completed by the original equipment manufacturer (OEM) or third party included the opening of the hook and removal of the pin for inspection.

Related safety flashes

-

IMCA SF 21/19

4 September 2019

-

IMCA SF 16/19

5 July 2019

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.