Hand crushed during coiled tubing reel handling

- Safety Flash

- Published on 4 September 2025

- Generated on 5 March 2026

- IMCA SF 16/25

- 2 minute read

Jump to:

Workers hand crushed during the final stages of a coiled tubing operation.

What happened?

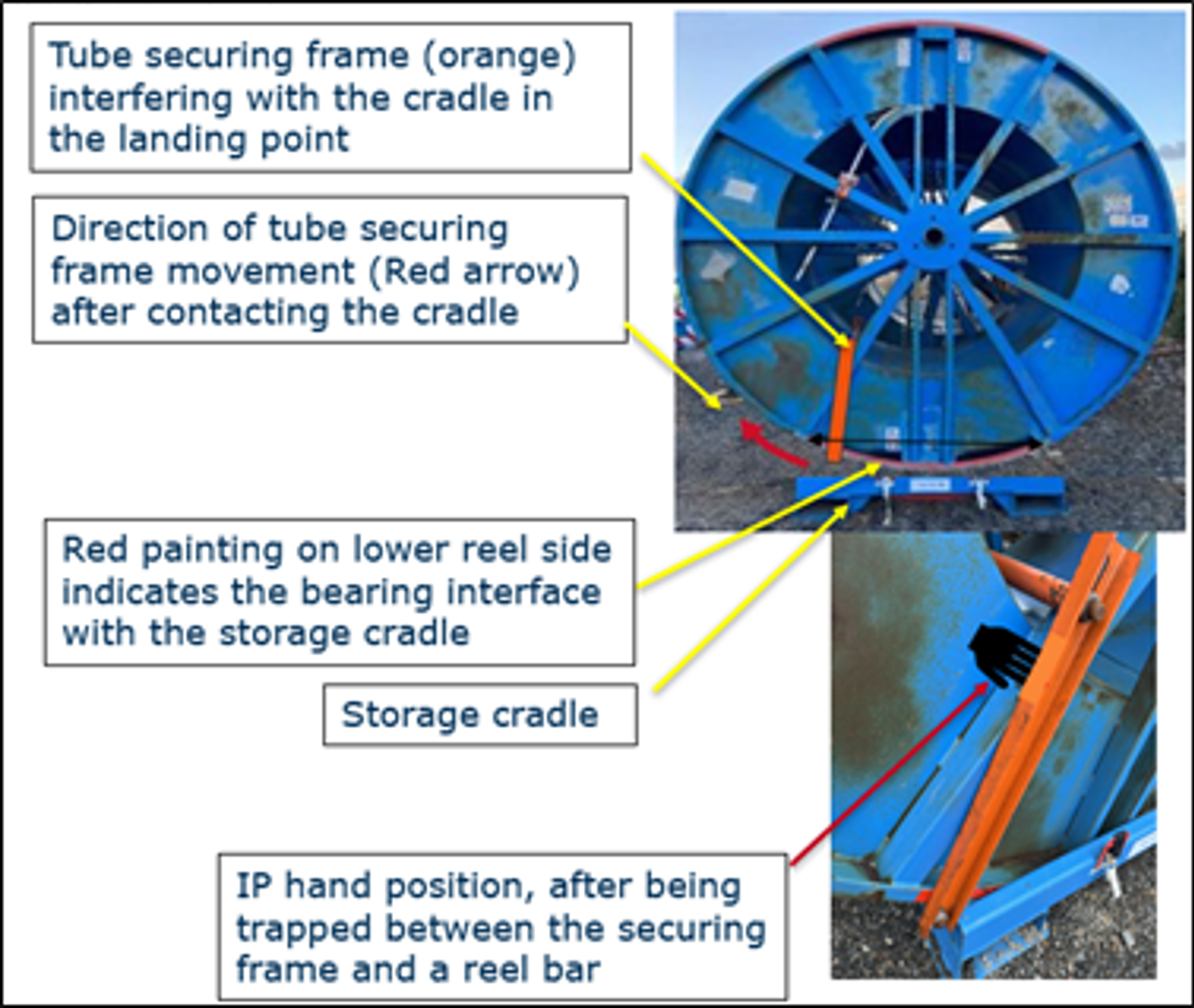

During the final stages of a coiled tubing operation, a completed reel was being lifted from the spooler and lowered into a support cradle. The reel, weighing 2600 kg (without tubing), was being aligned manually by the injured person, who placed their left hand on the reel to assist with positioning.

As the reel was landing, the tube securing frame on the reel contacted the side of the support cradle and shifted. This movement trapped the worker’s hand between the tube securing frame and a reel bar. The lift was immediately halted, and the securing frame was released. The worker was transported to a local hospital, and treated for severe crush injuries, resulting in partial amputations of three fingers of the left hand.

What went wrong?

- The injured person used a tag line but also placed a hand on the reel for alignment.

- The design of the tube securing frame allowed the potential for the entrapment of body parts.

- There were inadequate instructions or specifications regarding the safe operation of this securing frame which was supplied equipment.

- Capturing the risks:

- The hazard identification and risk analysis did not fully identify risks associated with lifting the reel;

- The Toolbox Talk (TBT) didn’t fully cover the lifting operation.

Lessons learned

- Safer by design: review design of equipment for potential entrapment hazards;

- Risk Assessment: update hazard identification and risk analysis to include all operational phases, including lifting and alignment;

- Training & Awareness: Reinforce the importance of hands-free load guiding and proper use of tag lines/push pull poles;

- Communication:

- Ensure all equipment-specific instructions are requested and reviewed before operations;

- Ensure there is a clear process for, and full understanding of, new equipment familiarization.

- Toolbox Talks: Quality of Toolbox Talks can be improved by the adoption of ‘Useful HOP Questions’.

Related Safety Flashes

-

IMCA SF 05/25

19 March 2025

-

-

IMCA SF 10/25

4 June 2025

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.