Failure of webbing strop during lifting operations

- Safety Flash

- Published on 3 December 2008

- Generated on 30 June 2025

- IMCA SF 17/08

- 3 minute read

Jump to:

A Member has reported an incident in which a webbing strop failed during a lifting operation onboard a vessel.

What happened?

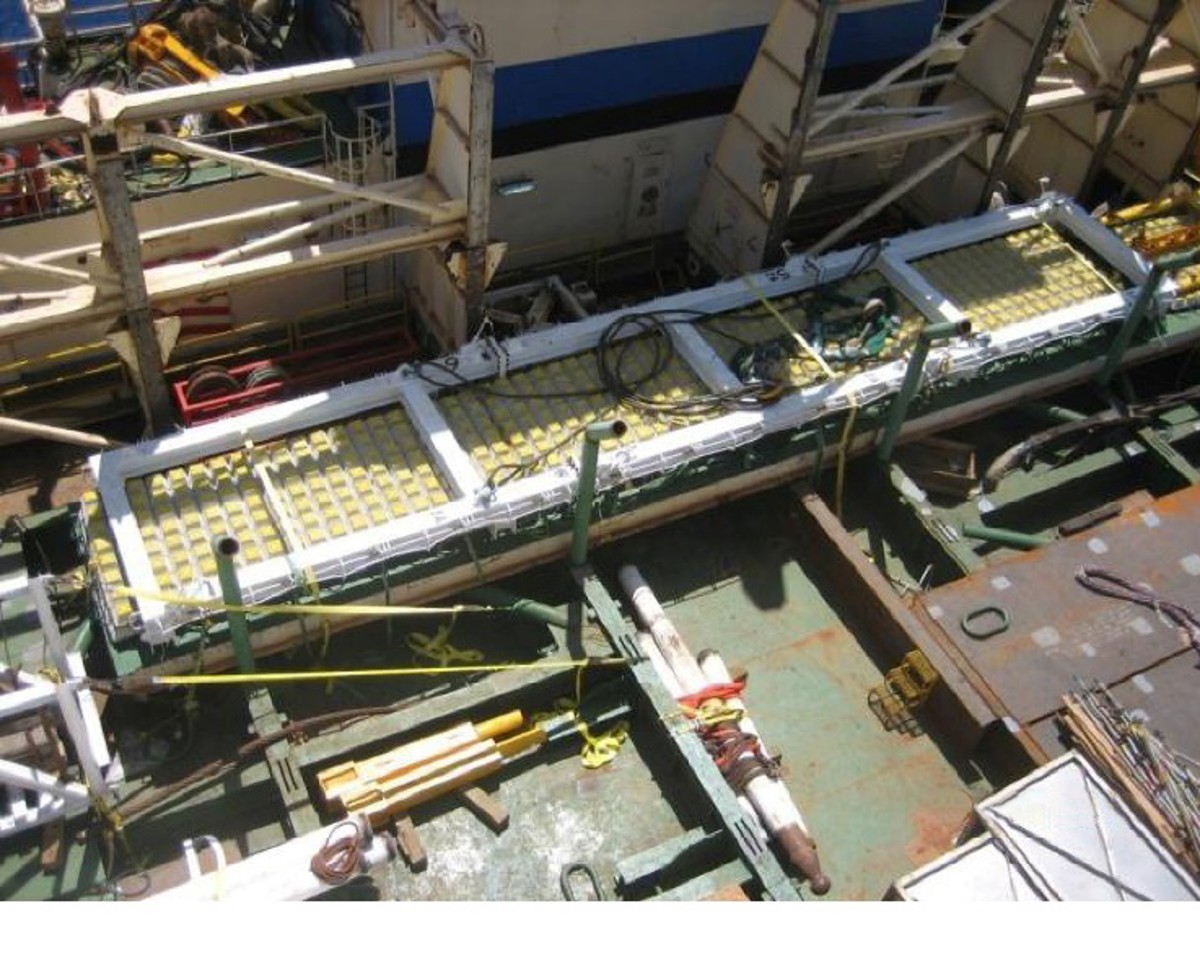

The rigging crew found it necessary to reposition the mattress lifting frame which had been landed incorrectly. The lift was being carried out to reposition the lifting frame at one end, in order to square it up, as the forward section was not sitting correctly on the mats.

The weight of the handling frame and rigging was 9.2Te. A webbing strop with a safe working load (SWL) of 3.6Te was selected. The sling was then basket-rigged to give a SWL of 5.8Te, attached to the main lift rigging of the handling frame and then on to the crane whip line block.

With all personnel clear of the load, the rigging foreman instructed the crane operator to commence the lift. As the weight of the lift was taken on the crane the rigging parted, causing the frame to land back in place. No one was injured. The crane computer showed a peak load of 9Te.

Following investigation, these conclusions were drawn:

- The sling was incorrect for carrying out this lift. It was not only an insufficient SWL but was also worn and in a generally degraded condition. There were no ID marks or colour codings on the sling.

- The sling was not subject to inspection prior to use and as such the wear and lack of ID was not observed.

- The intention had been only to lift up one end of the frame. However, with no adequate lift planning in place, the sling was connected to the central lifting point; . An assumption was made that this sling would be of a sufficient SWL when basket-rigged to lift one end only.

The following actions were recommended:

- The need for an appropriate lifting plan for every lift, however small or ‘routine’, should be reiterated.

- All vessels should check their items of lifting equipment and rigging to ensure that they have appropriate and readable ID markings which are part of a vessel’s itemised rigging, are free from defects and are included in regular planned inspection.

- Personnel should ensure they are familiar with the relevant lifting operation procedures including documentation and lift planning.

- members should ensure that relevant information on lifting – including pocket safety cards, posters and procedures – is available at worksites and vessels.

- Use of generic lifting plans should be scrutinised to ensure their suitability.

Members’ attention is also drawn to Guidelines for lifting operations.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.