Dropped object during cable trans-spooling

- Safety Flash

- Published on 29 August 2024

- Generated on 7 March 2026

- IMCA SF 17/24

- 3 minute read

Jump to:

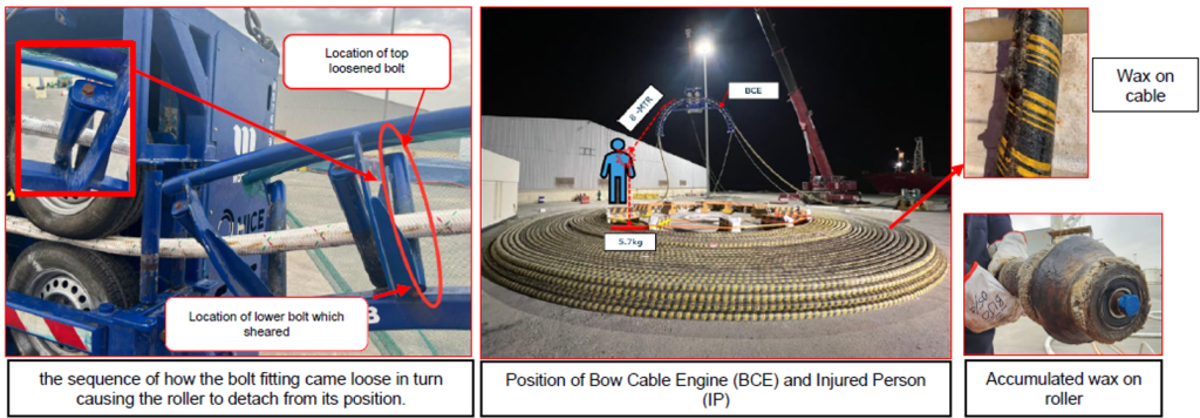

A roller weighing 5.7kg fell 8m and hit someone on the shoulder.

What happened?

This high potential incident occurred during alongside when a 69kV electrical cable was being trans-spooled ashore from a third party vessel. A connection bolt failed, allowing the roller to fall from a suspended Bow Cable Engine (BCE). On disconnection it dropped, first striking and being deflected by the BCE, before hitting the right shoulder of one of the subcontractor’s workers. The worker was underneath and close to the BCE as their task was to guide the cable as part of coiling it for storage. Work was stopped and the person injured was taken transported to external medical facility for assessment and X-rays. The X-rays revealed no breaks and the person injured was fortunately able to return to work.

What went wrong?

- The injured person was working under a suspended load.

- The company had a Safe Use of Work Equipment assessment process, which was not applied.

- Existing risk assessments were inadequate. Additional measures to prevent dropped objects, such as secondary retention or cargo nets on the BCE, were not taken into account.

- The cable had to be offloaded to shore because of last minute unavailability of a cable laying vessel (third party). This introduced the additional risks of double handling and a new work site scenario;

- There was wax on the cable (this was a requirement from the client.)

- The fact that there was wax on the cable had not been adequately communicated by the manufacturer. As a result the process and relevant task plans were inadequate to deal with the additional risks introduced by the wax.

- The high ambient temperature at the work site caused the wax to melt.

- The friction on the cable was affected by the wax. The melted wax prevented the BCE and its rollers from functioning properly.

- There had been potential windows of opportunity to raise a “Management of Change” before the incident which may have identified further controls to address the excessive wax. These opportunities were missed.

Actions taken

- Ensure effective application of the Management of Change (MoC) process to assess and manage the identified changes including identification and assessment of risks.

- Be curious – keep questioning all aspects of what may go wrong. Take the time to go through all potential risks to consider and implement adequate mitigation controls.

- Everyone should feel able to stop the job, ask questions, assess, and only then, act.

- Guard against becoming complacent by continually asking the question “what if …?”

- Remember the wax that no-one had taken into account? Ensure better communications with relevant parties to ensure everyone involved understands what is being delivered before it arrives.

Related Safety Flashes

-

IMCA SF 24/22

1 November 2022

-

-

IMCA SF 17/21

16 June 2021

-

-

IMCA SF 09/21

30 March 2021

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.