Near miss: Failure of subsea lifting equipment

- Safety Flash

- Published on 25 July 2017

- Generated on 21 February 2026

- IMCA SF 18/17

- 2 minute read

Jump to:

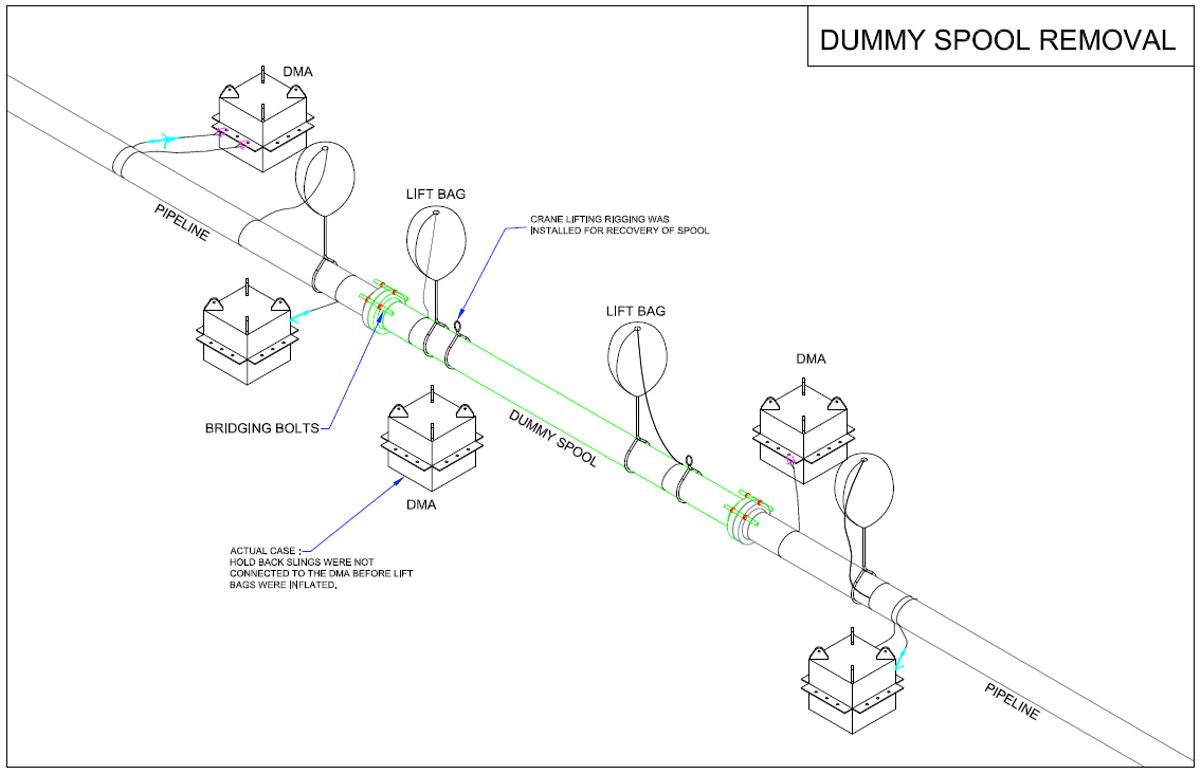

A dummy spool connected to two lift bags made a rapid and uncontrolled ascent to the surface.

What happened?

The incident occurred during diving operations on a construction barge. There were no immediate consequences but the event had potential to cause serious injury to personnel and damage to assets.

Divers were carrying out a dummy spool removal activity on the seabed at a depth of 110 fsw. As the last bolt was being removed the spool section broke free and rapidly ascended to the surface.

When the bags arrived at the surface they lost some of their volume, resulting in partial deflation, and the load fell back to the seabed, away from the dive site. The load was later safely recovered to the deck of the barge.

What went wrong? What were the causes?

Investigation suggested that the immediate cause was the absence of hold-back lines from the spool section to suitable fixed anchoring points.

The lift bags had been inflated without appropriate ‘hold-back rigging’ in place and that there had been a failure to follow company procedures, handover instructions and guidance detailed in IMCA D016 – Guidance on open parachute type underwater air lift bags.

It was also noted that the dive plan had listed ‘install lift bags complete with hold-back rigging to the DMA’ as a specific activity requiring supervisor verification and sign-off on step completion.

The risk had also been identified in the risk analysis and appropriate mitigations defined. In addition, dedicated dead man anchors (DMAs) had been deployed to the seabed for use as anchoring points.

What lessons were learned?

Post incident debriefs and ‘times out for safety’ were held with the dive teams, including details of the incident, review of video footage and sharing key lessons learnt, identifying the following lessons to ensure that:

- the dive plan is read, understood and followed

- mitigations identified in risk assessments are applied stringently

- the diving task is conducted following company working procedures

- the diving task and company procedures follow IMCA recommendations on any diving operation

- dive supervisors fully understand their ownership and accountability for the activities with which they are tasked.

Members may wish to review the following incidents and guidance:

- IMCA LR007, D016 – Guidance on open parachute type underwater air lift bags

Related safety flashes

-

IMCA SF 05/12

8 June 2012

-

IMCA SF 15/08

9 October 2008

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.