Broken equipment repaired or replaced

- Safety Flash

- Published on 17 November 2025

- Generated on 21 February 2026

- IMCA SF 21/25

- 3 minute read

Jump to:

What happened?

A member highlights several cases of emergency equipment being broken or unserviceable.

1) Fire fighting pump:

On a vessel being dry-docked for cleaning of the box cooler system, it was noted that the firefighting pump for the dock was not operational and line not pressurized. The issue was taken to the management of the dry-dock and the fire fighting system was energised and made operational.

|

|

Members may wish to refer to:

• IMCA HSS 032 Guidance on safety in shipyards

2) Immersion suit:

During a monthly inspection, it was observed that the zipper in an immersion suit zipper was sticking and not functioning properly. The company was promptly informed, and a new certified immersion suit was delivered on board without delay.

Members may wish to refer to:

• Wear a life-jacket!! (MAIB)

3) Broken emergency exit handle:

It was observed that the handle of one of the emergency exits located on the main deck was broken. A broken handle on an emergency exit door can delay evacuation during emergencies and put crew members at risk. It may cause panic or overcrowding at alternative exits, further slowing down escape. The handle was repaired immediately.

|

|

4) “Perished” rubber on Ventilation Flap:

During a scheduled fire drill, the crew attempted to close all the ventilation flaps located on the main deck. These flaps are critical to fire safety, as they are designed to restrict the flow of oxygen and assist in extinguishing fire. It was observed that one ventilation flap would not close fully. This was because of deterioration of the rubber seals, which had dried out and worn, preventing a proper airtight seal. This condition was not identified earlier during routine inspections.

-

- Action was taken to replace the defective rubber seals on the affected ventilation flap, and inspect all other ventilation flaps and seals on board to identify any similar deficiencies. A condition check of rubber seals was added to the planned maintenance system, and care was taken to ensure spares were held on board.

· Incomplete closure of ventilation flaps could allow continuous airflow to a compartment during a fire, potentially fuelling the fire and reducing the effectiveness of fire-fighting measures.

Members may wish to refer to:

· Proper care of oxy-acetylene cutting and welding equipment

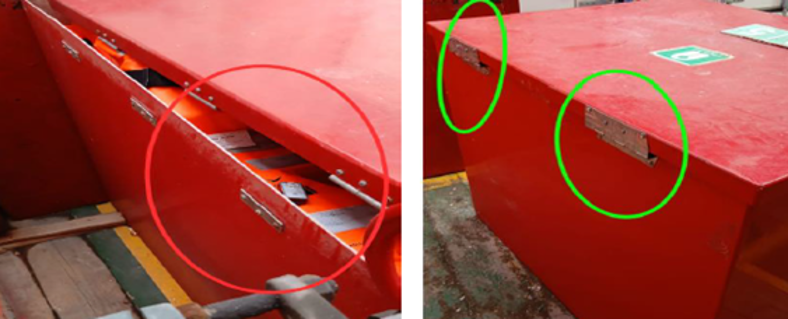

5) Damaged Hinges on Lifejacket Storage Box:

It was observed that the hinges of the box storing lifejackets were broken. In an emergency, crew members should be able to open the LSA (Life-saving Appliances) box quickly to access lifejackets. Broken hinges could prevent the lid from opening, causing critical delays and posing serious risks to crew safety. Additionally, unsecured lids may allow seawater ingress or accidental loss of equipment.

-

- The issue was immediately reported to the Chief Officer, who immediately arranged for repairs. Arrangements were made for regular inspection and maintenance of such boxes, with particular attention to hinges and securing arrangements.

Though all of these are of themselves relatively “minor” safety issues in the greater scheme of things, the cumulative effect of lack of attention to detail on such matters could have serious consequences. This is particularly true of all equipment but particularly safety equipment:

- Equipment that is only used in an emergency.

- Equipment that is not easily visible or accessible.

- Equipment that is exposed to the elements.

Consideration may be given to checking everyday details of safety equipment at regular intervals – hinges, seals, zips, handles etc.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.