LTI – fingertip pinched by wire sling

- Safety Flash

- Published on 3 October 2023

- Generated on 3 March 2026

- IMCA SF 23/23

- 2 minute read

Jump to:

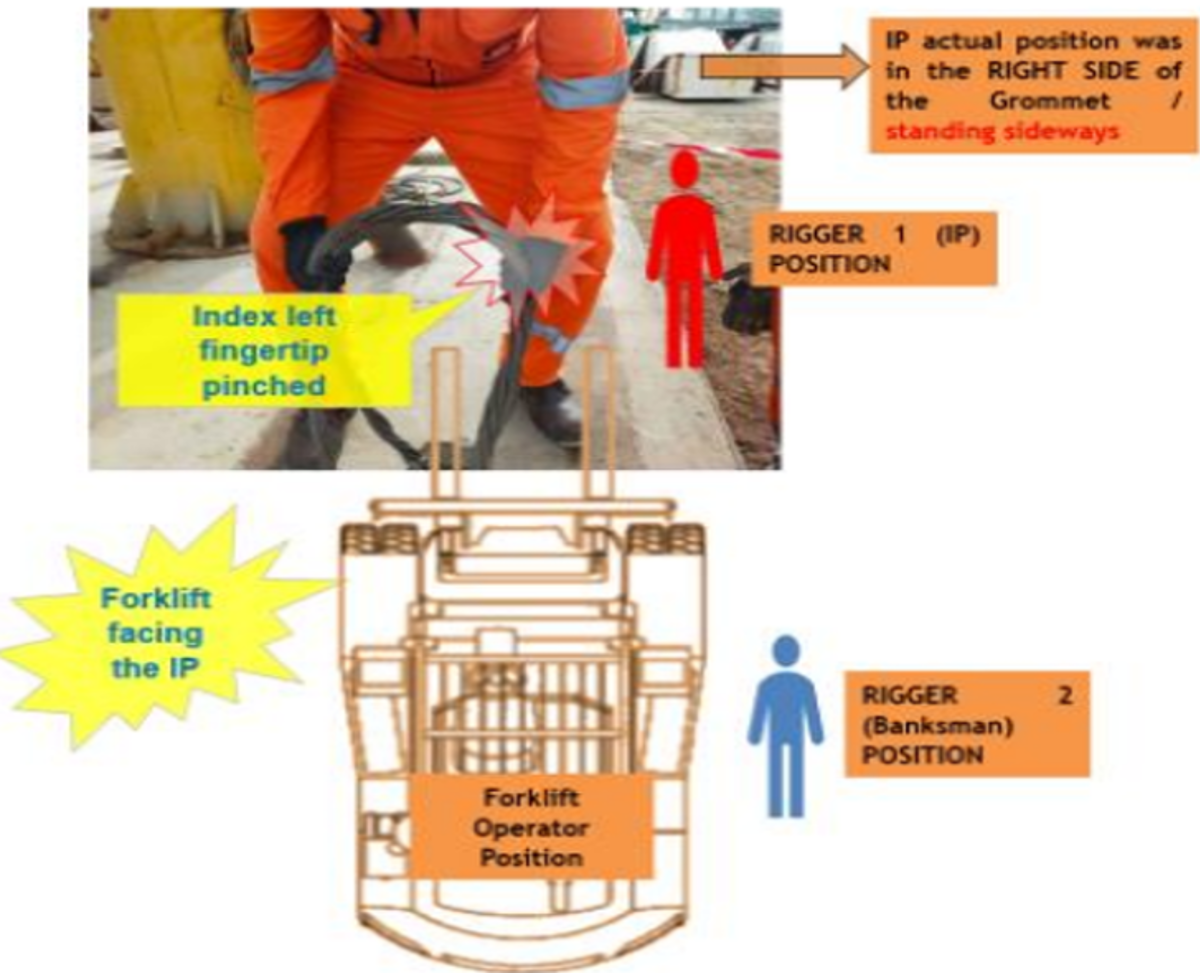

A rigger suffered serious injury when his finger got trapped between a sling and one of the forks of a fork-lift truck.

What happened?

The incident occurred when the rigger was installing a steel wire sling on one fork of the fork-lift truck in stand-by, and the fork-lift operator started to lift the fork without instruction or alert from the banksman nearby.

What went wrong?

- The experienced fork-lift operator started to lift the fork without any instructions, without any reference to the Banksman who was the person through whom communication ought have been channelled.

- The rigger took no account of the fact that his fingers were IN THE LINE OF FIRE.

- Neither the task nor its risks were suitably assessed by the lifting team.

What were the causes?

Our Member identified the following as causes:

- complacency – the fork-lift operator acted without thinking, based on previous experience

- lack of communication.

Lessons learned

- Always wait on clear instructions or signals from the Banksman during lifting operations, particularly if you don’t have a clear overview of the work area.

- Think through where you position yourself – keep out of the line of fire.

- Ensure everyone involved in the task takes part in, and is properly briefed at, a toolbox meeting before starting, and that this meeting covers all the hazards involved.

- Our Member took steps to arrange for this particular task to be done in a different way in order to prevent recurrence.

Related safety flashes

-

IMCA SF 29/20

9 October 2020

-

-

IMCA SF 28/16

18 October 2016

-

IMCA SF 05/11

29 June 2011

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.