Pollution caused by burst hydraulic hose

- Safety Flash

- Published on 1 April 2005

- Generated on 23 February 2026

- IMCA SF 05/05

- 2 minute read

Jump to:

A Member has reported a pollution incident which occurred during recent diving operations.

What happened?

A hydraulic torque tool was deployed with the ship’s hydraulic down-line. The planned intervention was to operate a sub-sea valve. However, the hose failed and some 200 litres of hydraulic oil were lost to sea. No divers were harmed by the event.

The hose certification was checked and found to be in-date. The hose was being operated within its specified pressure limits, but the failed section of hose was removed and inspected. The outer cover of the hose appeared to have been damaged through abrasion or scraping on a rough surface or sharp edge. The nature and colour of corrosion on the hose braiding indicated that the damage had originally occurred some weeks before rather than just prior to the failure.

What were the causes?

The subsequent investigation revealed that the inspection regime onboard had failed to visually detect an obvious area of damage to the hose prior to its deployment.

Actions

Our Member recommended the following actions:

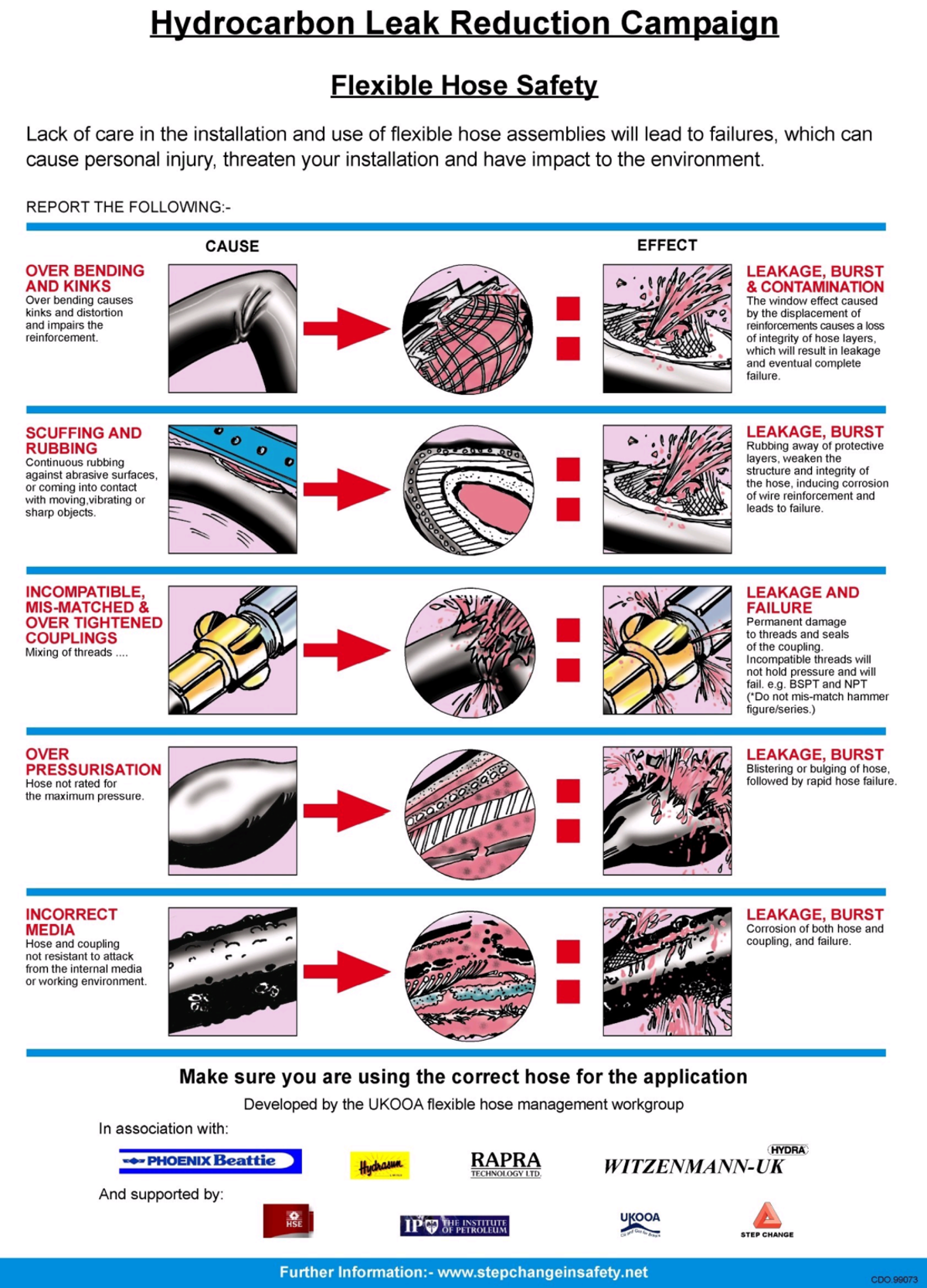

- Hoses to be reeled out on a regular basis and inspected thoroughly for damage, including connectors. See the attached poster (courtesy Step Change in Safety/UKOOA) for information regarding types of damage and failure mode.

- Frequency of above inspection should be commensurate with the utilisation: the more utilisation the shorter the period between inspections, but all hoses to be inspected not less frequently than every six months.

- Maintain a written log of inspections including the name of the person inspecting.

- Appropriate responsible person, for example, deck foreman and/or chief engineer, to verify that the inspection regime is followed and that suspect equipment is quarantined and replaced.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.