High potential near miss: Dropped object during piggyback drilling operations

- Safety Flash

- Published on 16 July 2019

- Generated on 3 July 2025

- IMCA SF 17/19

- 2 minute read

Jump to:

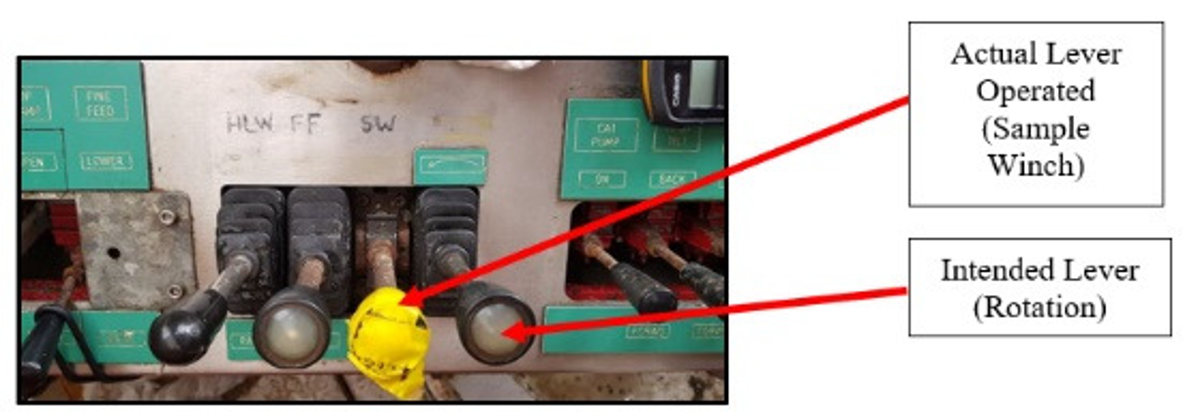

During piggyback drilling operations, a driller inadvertently operated the sample winch control lever instead of the power swivel fast rotation control lever as intended.

What happened?

Activating the sample winch caused a tool to rise from its storage position, resulting in it snagging on a safety hoop of the adjacent vertical fixed access ladder.

The tool (weighing 11 kg) separated from the wire and fell approximately 8 m onto the drill floor below. There were no injuries and no equipment was damaged.

What were the causes?

- The operating driller moved the wrong lever unintentionally.

Investigation noted the following:

- The tool (an ‘overshot’) was connected to the sample winch wire via a weak link shear pin designed to separate at 450 kg. The sample winch has a working load limit of 1.2 tonne.

- The experienced driller had not operated this particular type of drill rig control console for several years; however, he had received a short period of familiarisation training during the previous shift under the guidance of the back-deck supervisor.

- The control console ergonomics and inspection and maintenance requirements had not been properly considered:

- the possibility of inadvertent operation of the wrong lever had not been identified when the piggyback drilling equipment was installed some months before the incident

- there is no evidence that this had been taken into account (in 1995) when the piggyback drill was designed.

- the possibility of inadvertent operation of the wrong lever had not been identified when the piggyback drilling equipment was installed some months before the incident

- There had been ineffective checking and assessment of the suitability or fitness for purpose of this equipment.

What lessons were learned?

- Undertake a design review and complete a design risk assessment on all similar drilling rigs:

- to include the operational and human interface with the drill rig and associated equipment

- planned preventative maintenance check sheets should be updated to reflect the findings of this assessment.

- to include the operational and human interface with the drill rig and associated equipment

- Control consoles should be clearly labelled to identify all controls and their function.

- Develop a thorough familiarisation assessment process for the operation of this kind of equipment.

Related Safety Flashes

-

IMCA SF 12/19

28 May 2019

-

-

IMCA SF 03/02

1 April 2002

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.