LTI: Serious hand injury – fingers lost in unexpected hatch closure

- Safety Flash

- Published on 13 July 2023

- Generated on 22 February 2026

- IMCA SF 17/23

- 2 minute read

Jump to:

A crew member was badly injured when the engine room’s emergency hatch cover closed unexpectedly on his fingers

What happened?

A crew person was checking the water tightness of the engine room’s emergency hatch cover.

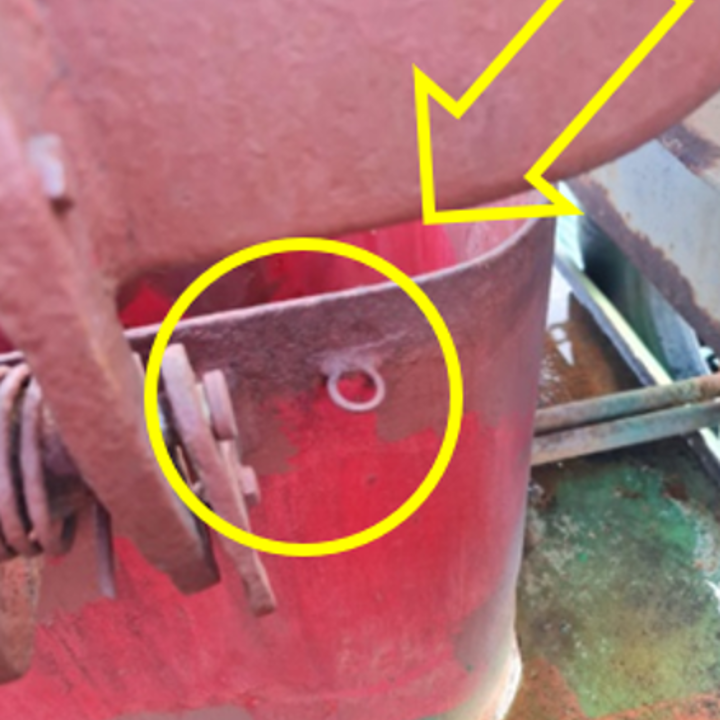

Safety lock pins, used to prevent the hatch cover from closing, were missing.

To hold the hatch cover from closing, the crew person improvised using a nearby chain which he hooked to a hose support. However, the improvised arrangement failed and the hatch cover closed unexpectedly.

The injured person had his left hand in the mouth of the hatch, and the hatch cover landed on his fingers. The tips of his two longest fingers were very badly injured, and had to be amputated.

This incident contains a link to a graphic photograph of the injuries sustained.

Safety lock pins missing

Hatch cover held by chain and hooked to a hose support

Hatch cover held by chain and hooked to a hose support

Hand trapped by fallen hatch (RE-ENACTMENT)

What went wrong?

- Poor spatial awareness: the injured person was not aware of the pinch point; therefore he didn’t stop the job when he saw that there were no safety lock pins on the hatch.

- The injured person improvised an inadequate and inappropriate method of securing the hatch cover.

- The toolbox talk did not highlight potential hazards such as line of fire, pinch point, etc. and its mitigation.

What was the cause?

Our Member notes the cause as being an inadequate planned maintenance system which did not highlight the lack of safety-critical locking pins.

Actions

- Review and modify existing planned maintenance system onboard to ensure it is properly implemented and is not just a “checklist tick”.

- Reiterate importance of thorough toolbox talks before the job – take the time to think things through.

- Don’t just improvise safety equipment – stop the job, think it through, get it right.

- Are there areas in your work where you might be tempted to “just do it anyway?” without the right safety equipment?

Members may wish to refer to the following graphic image of the crew member's injured fingers.

Related safety flashes

-

IMCA SF 05/23

16 February 2023

-

-

IMCA SF 33/20

6 December 2020

-

-

IMCA SF 06/19

5 April 2019

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.