Crane anti-two block securing wire failure

- Safety Flash

- Published on 25 July 2019

- Generated on 23 February 2026

- IMCA SF 18/19

- 2 minute read

Jump to:

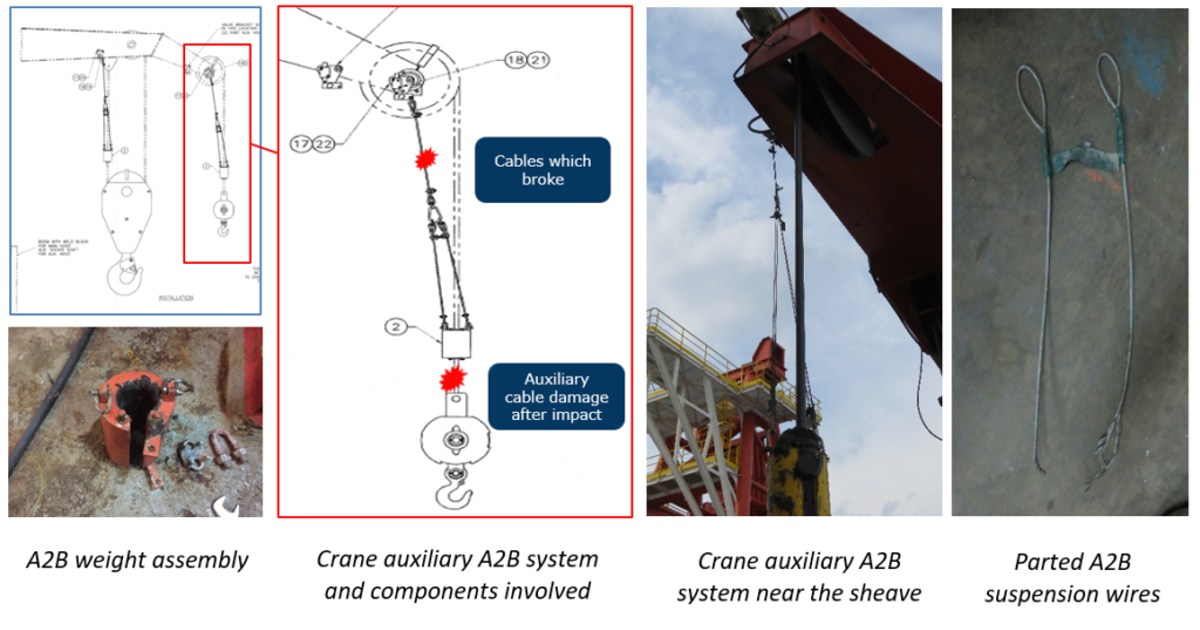

During routine lifting activities, a vessel crane’s (auxiliary) anti-two block (A2B) suspension wires failed, causing the A2B weight assembly to fall along the crane wire to the crane block.

What happened?

Lifting operations were suspended and an inspection was conducted on the auxiliary crane wire and A2B system.

No injuries to personnel were sustained as result of the incident.

What were the causes?

- During inspection and function test of the A2B system, the actuation lever was found seized.

- Testing and inspection had not been carried out in accordance with equipment operating instructions.

- The crane operator’s daily checklist noted ‘testing’ of the A2B system. However, it was found that only visual inspections were performed.

- The upper A2B suspension wires had parted at a position and in a fashion which suggested that the wires were severed by contact with the crane sheave and/or auxiliary wire. It is probable that the seized actuation lever prevented the A2B system from functioning correctly, allowing the crane block to pay-in past the ‘cut off point’, causing slack in the suspension wires and contact with the sheave.

What lessons were learned? What actions were taken?

- Full and thorough inspection of crane A2B systems to confirm that they are maintained, functioning correctly and free of potential seizing (of the actuation level).

- Inspection of equipment holdbacks/retention wires to identify potential for slack and/or entanglement with moving parts. Consider replacing wires with larger diameter.

- Always comply with equipment pre-start checklist requirements, including function testing of equipment where specified.

- Inspections should be appropriately documented to record subsequent findings/corrective actions, and records reviewed appropriately on a regular basis to verify effectiveness.

Members may wish to refer to:

- IMCA HSS019 - Guidelines for lifting operations

- IMCA safety promotional video: Be prepared to work safely - Lifting operations

- IMCA safety promotional video: Be prepared to work safely - Lifting equipment

Related Safety Flashes

-

IMCA SF 09/18

24 April 2018

-

-

IMCA SF 11/08

23 June 2008

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.