High potential near miss: Nitrogen hose failure during transfer of gas

- Safety Flash

- Published on 25 August 2020

- Generated on 23 February 2026

- IMCA SF 25/20

- 2 minute read

Jump to:

What happened?

As nitrogen gas was being transferred from the pipelay tower accumulators to storage bottles located within the pipelay HPU room, the pipelay supervisor noticed a sudden drop in pressure. He immediately went to the door of the HPU room to assess the situation.

He could hear the sound of a high pressure gas release within the room, and decided not to go in. He ran to the nearest emergency stop button located on the main deck to stop the system.

What were the causes?

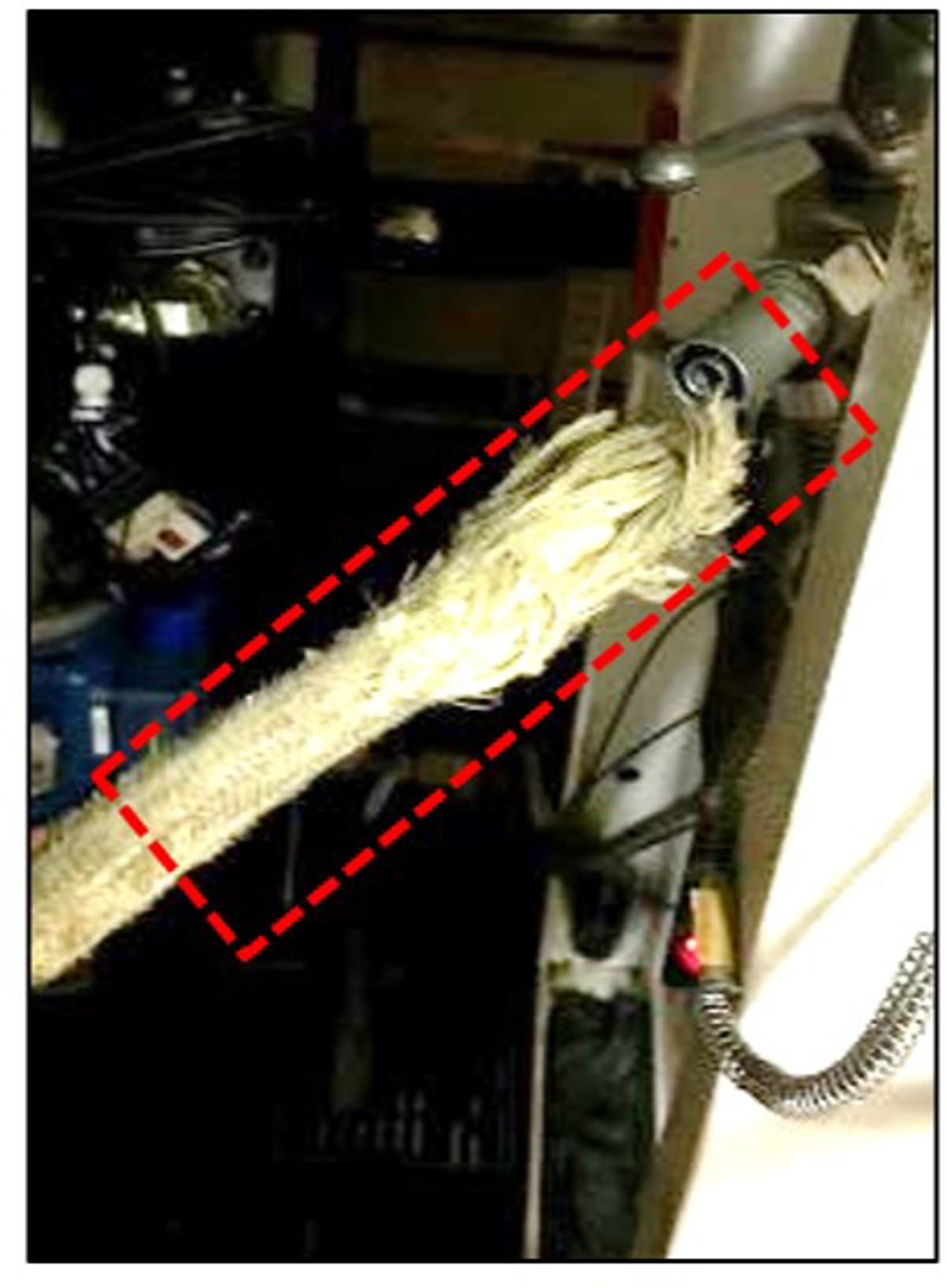

The hose had been in place since 2010 and there was substantial degradation along its full length.

The hose was not identified on a hose register and therefore not subject to any planned maintenance or inspection regime.

What went wrong?

It was later identified that a supply hose had detached from its ferrule and approximately 165,000 litres of pure nitrogen was released into the room. Consequently this reduced the oxygen levels in the room to approximately 17.4% (normal oxygen content in the atmosphere is 20.8%).

Actions

- All pressurised hoses should be correctly secured and coupled using properly rated hose whip check restraints.

- All hoses and fittings should be visually inspected prior to use and should be examined regularly in service for wear and should be changed out as necessary or as part of a planned maintained schedule

Our member also:

- Ensured adequate ‘Restricted Access’ signage is posted at all entrances to the nitrogen storage area.

- Ensured suitable low oxygen detection alarms are installed within the immediate area.

Members may wish to refer to

- IMCA D065 Guidance on the use of whip checks (hose restraints)

Related Safety Flashes

-

IMCA SF 08/19

25 April 2019

-

-

IMCA SF 31/17

15 December 2017

-

-

IMCA SF 21/16

10 August 2016

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.