- Discover how we are helping Members reduce emissions: Explore the ProjectGHG hub now.

- Join the global DP Community at the IMCA DP Conference in Amsterdam. 21 and 22 May. Book now

- Register your interest for the IMCA Global Summit 2024. 3-4 December, Utrecht, Netherlands.

- Now booking. Underwater Ship Husbandry Seminar. 10 October 2024, Singapore.

Injury sustained during manual handling of sharp object

What happened?

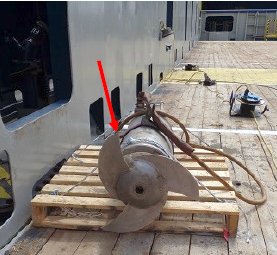

A crew member injured his leg while moving a mud agitator with unprotected blades. At the time of incident, the vessel was proceeding to port. First aid was administered immediately on-board, followed by further examination and treatment of the wound at a clinic onshore. The injured person returned to the vessel on the same day.

What went wrong? What were the causes?

- There was inadequate risk awareness – risks could have been reduced by protecting the blades before lifting/handling the agitator; waiting until the vessel reached port could also have reduced manual handling risks;

- Manual handling practice could have been improved – while the agitator was suspended by chain blocks during the work, whilst gripping the blades using pieces of rags (rather than wearing gloves), the load slipped from his hands and hit the crew members’ leg. A rope or another hands-off approach could have been used to turn/move/stabilise the load.

What actions were taken? What lessons were learned?

- Better risk awareness when moving objects with blades or sharp edges:

- protect the sharp edges

- arrange lifting and moving of load without actual manual handling – ropes, tag lines etc

- wait until more personnel are available and/or vessel is in port (as appropriate)

- use proper personal protective equipment (PPE) – gloves.

Members may wish to refer:

- Crewman suffers cut to hand – but gloves prevented it being much worse

- Two recent cases of hand and arm injuries

- Watch your hands [‘Be prepared to work safely’ video]

Safety Event

Published: 9 November 2018

Download: IMCA SF 25/18

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.