- Discover how we are helping Members reduce emissions: Explore the ProjectGHG hub now.

- Join the global DP Community at the IMCA DP Conference in Amsterdam. 21 and 22 May. Book now

- Register your interest for the IMCA Global Summit 2024. 3-4 December, Utrecht, Netherlands.

- Now booking. Underwater Ship Husbandry Seminar. 10 October 2024, Singapore.

Dropped wooden block in conductor support frame

What happened?

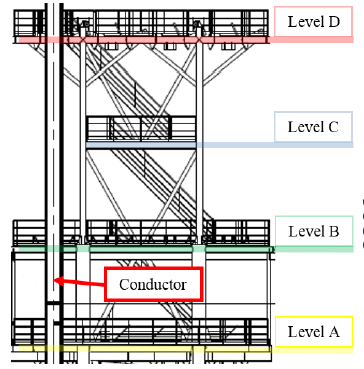

During a decommissioning project, a wooden wedge, weighing approximately 13 kg, dropped 6m, striking a rigger’s hard hat and shoulder on its way down. The rigger suffered minor cuts; it was fortunate that his injuries were not more serious. The incident occurred during decommissioning operations using a conductor support frame (CSF) to help with the removal of conductors. Conductors were pulled into position in the CSF by crane. To reduce horizontal movements, wooden wedges were installed, whilst the conductors were being cut in smaller sections. During removal of the wedges, one of the wedges fell and struck the rigger.

What went wrong?

As per company procedure, the wedges were to be placed into position at level B, to remove any horizontal movements of the conductor. To reduce movements from the top of the conductor, additional wedges were installed at level D (top level) of the CSF; this addition was not part of any procedure.

After completion of the sectioning cut at level A, the rigging team started to remove the wedges installed at level B, as per original procedure. Whilst removing the wedges at level B, one of the wedges installed at level D dropped to level B striking one of the riggers.

The investigation revealed that:

- Procedures had not been updated to include the additional wedges at level D;

- Management of change (MoC) was not implemented/followed;

- There was a failure of the wedge securing eyes due to vertical movement of the conductors caused by vessel/platform movement;

- It was not identified that removal of the (upper) level D wedges prior to removal of the (lower) level B wedges would have eliminated the dropped object risk.

What actions were taken? What lessons were learnt?

- Any change to a procedure should be subject to MoC;

- Procedures should be updated immediately and re-issued to include any changes;

- Any changes to procedures should be communicated to all personnel potentially affected by the change;

- All persons involved should take part in risk assessments/job safety analysis (JSA) in order to ensure all hazards are identified and eliminated/controlled.

Members may wish to refer to:

- Near miss: dropped magnet during dry docking

- Guidelines for management of change (IMCA SEL 001)

- IMCA DROPS videos:

- Technip DROPS (IMCA SEL 039)

- Saipem DROPS – choice not chance (IMCA HSSE 042)

- DROPS (IMCA HSSE 043) [shared by Subsea 7]

Safety Event

Published: 17 September 2019

Download: IMCA SF 22/19

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.