- IP Code: Mandatory Code enters into force on 1 July. Make sure your company is up to speed with the changes.

- Early Bird tickets available for the IMCA Global Summit 2024. 3-4 December, Utrecht, Netherlands. Members can save £400.

- Discover how we are helping Members reduce emissions: Explore the ProjectGHG hub now.

- Now booking. Join the Lifting and Rigging community at our Technical Seminar in Amsterdam. Thursday 12 September 2024

- Now booking. Underwater Ship Husbandry Seminar. 10 October 2024, Singapore.

Parting of hawser and bulk cargo hose during tandem mooring

What happened

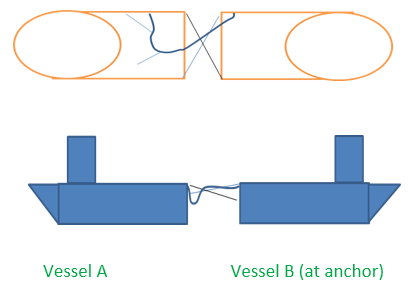

During at-sea bunkering operations between two vessels, a mooring line parted and then a fuel hose parted also. There was no spillage of fuel. The incident occurred when one vessel (Vessel A) arrived to deliver fuel to another vessel (Vessel B), which was at anchor with thrusters running.

It was decided to moor both vessels in tandem. Vessel B would maintain heading and control yaw using thrusters. Both vessels were moored to each other using one rope in a criss-cross fashion.

Vessel B could not start its fuel pump and thus the fuel transfer could not be started. The two vessels stayed connected in tandem.

The mooring rope from Vessel A parted due to jerking and continuous yawing. Crew on Vessel B were told to close the deck fuel valve and disconnect the hose for retrieval. The hose was disconnected and crew on Vessel A started retrieval using the port tugger winch. While they were retrieving the hose, it got entangled with the remaining single mooring rope and the vessel structure, and the hose parted on deck. No spillage was noticed as hose was empty.

The parted mooring rope and bulk cargo hose were retrieved by Vessel A.

What went wrong/causes

- There were 1.5m seas and wind of approx. 14 knots. Both vessels were yawing – the mooring ropes was getting intermittent jerks which resulted in one of them parting. The uncontrolled heaving of the bulk cargo hose resulted in it parting;

- Both vessels could have decided to call off or postpone the operation until the fuel pump was operational and/or weather would improve.

Members may wish to review the following incident:

Safety Event

Published: 25 July 2017

Download: IMCA SF 18/17

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.