- Discover how we are helping Members reduce emissions: Explore the ProjectGHG hub now.

- Join the global DP Community at the IMCA DP Conference in Amsterdam. 21 and 22 May. Book now

- Register your interest for the IMCA Global Summit 2024. 3-4 December, Utrecht, Netherlands.

- Now booking. Underwater Ship Husbandry Seminar. 10 October 2024, Singapore.

LTI: finger injury during work with rotating machinery

What happened?

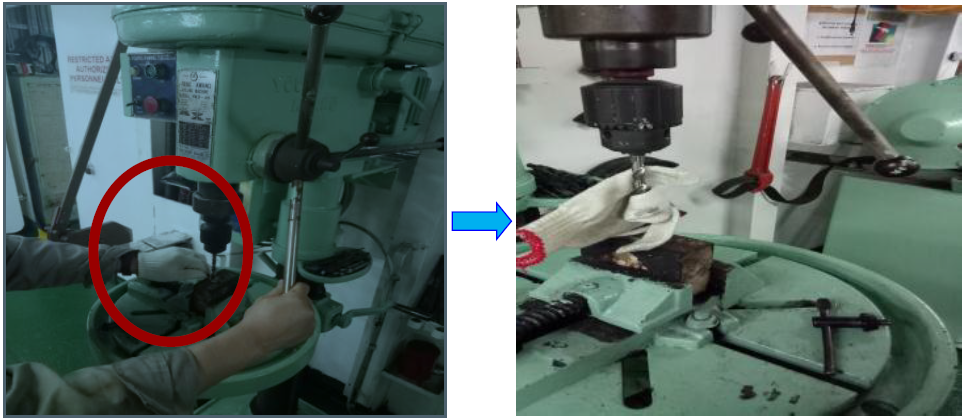

An electrician tried to modify a cable shoe using a pillar drill in the engine room workshop. During initial use of the drilling machine, the electrician secured the cable shoe with a vice and did not wear any gloves. However, during subsequent drilling to finalize/enlarge the hole, he did not secure the cable shoe properly, and he held it with his left hand whilst wearing cotton gloves, as the cable shoe had become too hot to touch.

His glove got entangled with the drill bit, resulting in a serious injury to his left index finger. Following first aid, he was medevaced by helicopter and transferred to hospital for further treatment. Medical examination revealed a partial amputation of his left index finger and open fracture dislocation of his thumb and damaged tendons, requiring surgery.

The injured person was not tired and was working appropriate hours at the time of the incident.

What went wrong? What were the causes?

- There was no evidence of any risk assessment, and a toolbox talk (TBT) was not conducted;

- The electrician was wearing gloves while using the drilling machine, though there was a warning sign prohibiting wearing of gloves when operating drill posted nearby;

- Immediate causes:

- improper use of personal protective equipment (PPE); glove got entangled with the drill bit

- carelessness; warning signage was ignored, and the cable shoe was not secured properly before drilling started;

- Causal factors:

- inadequate planning and lack of risk assessment

- electrician did not inform others of his intent to use the drill, and he was rushing to finish the work.

What lessons were learned?

- Gloves and loose clothing should not be worn when working with rotating machinery;

- “More haste – less speed” – avoid shortcuts and rushing to finish the job.

Members can refer to IMCA’s short video Watch your hands from the Be prepared to work safely safety promotion materials.

Members may wish to refer to;

Safety Event

Published: 13 February 2019

Download: IMCA SF 02/19

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.