- Discover how we are helping Members reduce emissions: Explore the ProjectGHG hub now.

- Join the global DP Community at the IMCA DP Conference in Amsterdam. 21 and 22 May. Book now

- Register your interest for the IMCA Global Summit 2024. 3-4 December, Utrecht, Netherlands.

- Now booking. Underwater Ship Husbandry Seminar. 10 October 2024, Singapore.

Lifting operation resulting in dropped objects from flexible intermediate bulk container

What happened?

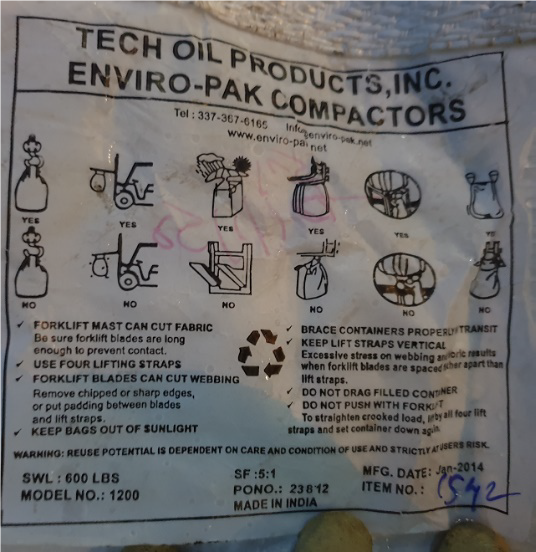

Multiple metal objects were dropped during a lifting operation using a flexible intermediate bulk container (FIBC). It was being used to lift garbage from a below deck stores area. The lift crew were unaware that several metal components ranging from 1.1kg – 2.3kg had been placed into the FIBC and then inadvertently covered over with cardboard and paper.

As the FIBC came through the hatch and over the main deck, high winds forced the FIBC into contact with the crane boom resulting in a shock load to the bag and the bottom tearing open. The lift supervisor called an all stop on the radio; however, this was not heard by the crane driver which then resulted in the contents being dropped across the deck and quayside.

The distance that the objects fell varied between 8 and 25 meters. The DROPS calculations indicate that multiple items had the potential to cause a fatality.

The job was stopped and a time out for safety carried out.

What actions were taken?

Our member’s investigation noted the following:

- Inspect FIBCs’ prior to use ensuring they are free from damage that can compromise its strength;

- Post signage next to any FIBC being used as a waste container indicating waste material type to be placed inside;

- Check FIBC contents (where practical) to ensure correct waste type is inside prior to lifting;

- Lift FIBC as per the manufacturer and supplier’s instructions;

- Consider the use of tag lines to control lifts where practical;

- Do not re-use FIBCs or use them for disposal of waste metals, wood, glass or other items than can puncture the bag;

- Ensure the vessel has the appropriate storage containers for scrap metal;

- Ensure that suitable lift baskets are available for the transportation or movement of loose items, such as metals, batteries etc.

Members may wish to refer to:

Safety Event

Published: 17 March 2020

Download: IMCA SF 10/20

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.